Training

Titanium Anodizing

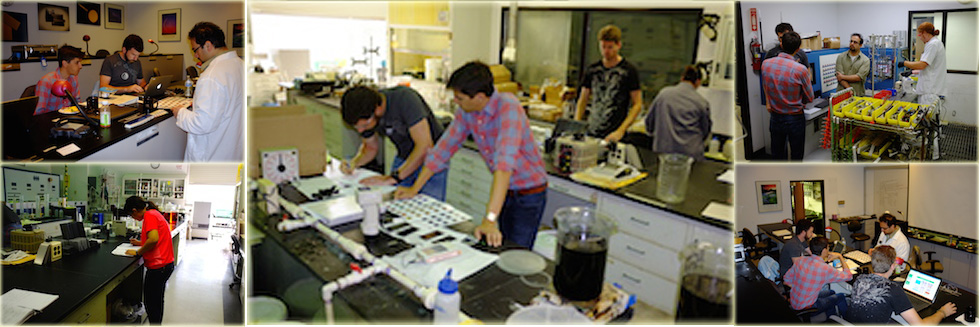

This full day class provides the participants with a broad range of information related to Titanium anodizing processes and history, the anodizing industry, process capabilities and limitations, as well as the benefits of process control. The course is held at CHEMEON’s Technology Center (Tech Center) in Minden, NV (Reno/Lake Tahoe). The class is written and taught by instructors with strong industrial experience background in the science.

Class Itinerary

- CHEMEON Technology Center (Tech Center) Tour, Course Overview and Introduction

- Titanium Anodizing Processes

- Titanium Anodizing Type I, II, III

- Benefits

- Inspection

- Titanium Alloys

- Racking

Process Cycles

- Discussion: Review of technical issues

- Laboratory Subjects

- Racking- Masking- Pretreatment- Type I, II, III Anodize- Color Anodize- Rack Selection- Mask Functionality

- Chemical Maintenance Subjects

- Deoxidizer Analysis- Color anodize analysis- Safety aspects of handling nitric acid and hydrofluoric acid

The second half of the day is devoted to anodizing in the Tech Center laboratory. While CHEMEON will have representative titanium samples available to work on, students are encouraged to bring their own materials for anodizing and discussion.

For questions or to schedule your training class, email Shay Davis at sdavis@chemeon.com or complete the inquiry form below.

Training Class Inquiry